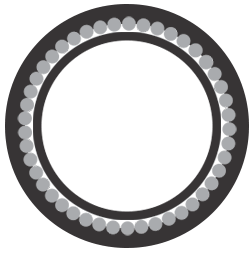

Flexible Foam Dielectric Copper Feeder Cable 1/2″

Model: (1/2″ F CU) KCPL50PE12A1

Model: (1/2″ F CU) KCPL50PE12A1

| Construction | ||

|---|---|---|

| Inner Conductor | Copper Clad aluminum Wire 4.80+0.15 mm | |

| Dielectric | Foamed polyethylene Nominal 12.50+0.30 mm | |

| Outer Conductor | Corrugated Copper tube Nominal 13.70+0.30 mm | |

| Jacket | Standard Black PE Nominal 15.70+0.30 mm | |

| Mechanical Characteristics | ||

|---|---|---|

| Weight (+5%) | Standard Jacket | Nominal 0.19 kg/m |

| Minimum Bending Radius (Single) | 70 mm | |

| Minimum Bending Radius (Repeated) | 125 mm | |

| Number of bends, minimum (typical) | 15 | |

| Bending moment | 5 Nm | |

| Flat Plate Crush Resistance | 1.30 kg/mm | |

| Operating Temperature | Standard Jacket | -40℃~+85℃ |

| Installation Temperature | -25℃~+60℃ | |

| Storage Temperature | -70℃~+85℃ | |

| Pulling Force | 113 Kg | |

| Electrical Characteristics | ||

|---|---|---|

| Max. Operating Frequency | 8.8 GHz | |

| DC Resistance | Inner Conductor | 1.70 Ω/km |

| Outer Conductor | 4.20 Ω/km | |

| Dielectric Strength | DC 4,000V For 1 Min | |

| Min. Insulation Resistance | 10,000 MΩ.km | |

| Velocity of Propagation | 87±3% | |

| Peak Power Rating | 40 kW | |

| Characteristic Impedance | 50+1Ω | |

| Capacitance | 75.8 pF/m | |

| Inductance | 0.19 µH/m | |

| Cut-off Frequency | 10.0 GHz | |

| Jacket Spark Test Voltage | 8000 Vrms | |

| VSWR | 800~1000 MHz | 1.13 |

| 1700~2200 MHz | 1.15 | |

| 2200~2700 MHz | 1.15 | |

| 3300~4000 MHz | 1.25 | |

| 4000~6000 MHz | 1.35 | |

| Frequency (MHz) | Attenuation dB/100m |

|---|---|

| 100 | 2.48 |

| 150 | 2.96 |

| 200 | 3.42 |

| 300 | 4.27 |

| 450 | 4.75 |

| 500 | 5.46 |

| 700 | 6.45 |

| 824 | 6.49 |

| 890 | 6.76 |

| 900 | 7.31 |

| 960 | 7.04 |

| 1000 | 7.73 |

| 1500 | 9.60 |

| 1700 | 9.61 |

| 1800 | 9.91 |

| 1900 | 10.42 |

| 2000 | 10.70 |

| 2100 | 11.42 |

| 2200 | 11.72 |

| 2300 | 11.40 |

| 2400 | 11.66 |

| 2500 | 12.58 |

| 2700 | 12.61 |

| 3000 | 13.44 |

| 3300 | 14.35 |

| 3500 | 14.70 |

| 3800 | 15.50 |

| 4000 | 16.00 |

| 4200 | 17.00 |

| 5000 | 18.42 |

| 6000 | 20.05 |

Contact Kanhha Cables for your return loss specification of your required frequency band.

“After the delivery of the cables against one of our RURAL ELECTRIFICATION (RE) project in Mozambique, TIRUPATI PLASTOMATICS TEAM was very apt in rendering the on-site training support related to installation aspects to our staff people which is exemplary and made our task lot more easier. We appreciate their POST SALES SUPPORT which was not a part of our contract agreement.”

“QUALITY is of paramount importance to our company and we are quite satisfied with the on-field performance of TIRUPATI PLASTOMATICS cables installed in our project”

“During the Pre-shipment inspection, we realized that the quality of workmanship of TIRUPATI PLASTOMATICS make cables is of highest quality. Their labs are fully equipped to perform all the ACCEPTANCE TESTS which were desired from our side. We would come back for the repeat purchase of the similar cables”

“Our Experience of buying the cables for our Metro Project had been very satisfying as they are operationally performing well in line with our desired standards. We vouch for the technical prowess of TIRUPATI PLASTOMATICS make cables.”

Our worldwide presence ensures the timeliness, cost efficiency and compliance adherence required to ensure your production timelines are met.

Complete control over products allows us to ensure our customer receive the best quality price and service. we take great pride in everything that we do in our factory.